Mar 28, 02 · Future acquisition for this item should refer to SAEAMSQQP416, "Plating Cadmium (Electrodeposited)" (Application for copies of SAE Aerospace Material Specifications should be addressed to SAE, 400 Commonwealth Drive, Warrendale, PA ) QQP416 Rev F Download File 754 KB Report Problem (email) StatusAMPHENOL SHRINK BOOT ADAPTER Amphenol shrink boot adapter is a good option when the unshielded cables are terminated with heat shrink boots It has a groove where the boot lip can be held which provides good grip apart from sufficient space inside for the cable loopingNov 10, 09 · I have a question and someone can help clarifying the definition of a lot in accordance with AMSQQP416 Para 4421 as follow "Lot shall consist of plated articles of the same basis metal composition, class, and type plated and treated under the same conditions and submitted for inspection at one time"

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Ams-qq-p-416 type ii class 2

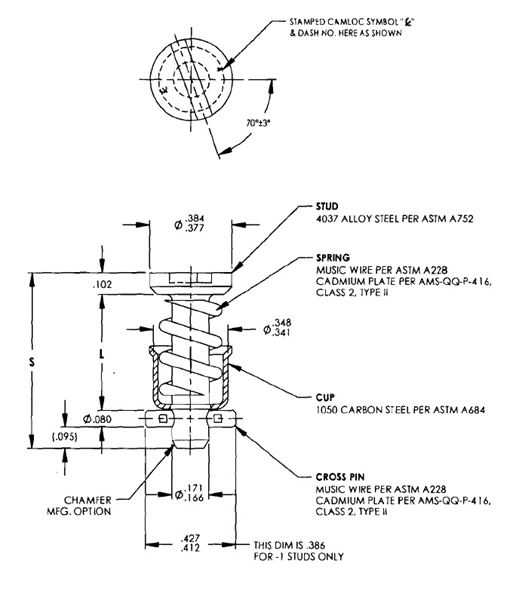

Ams-qq-p-416 type ii class 2-Anodize per MILA8625, Type II, Class 2, dyed color black and cetyl alcohol lubricantWasher Cadmium plate per AMSQQP416, Type II, Class 2PERFORMANCE KFS 1008, except one cycle useMISALIGNMENT Up to 7° maximum from centered positionAPPLICATION For use on standard to 032 oversize shank boltsPACKAGING Parts are normally suppliedJul 01, 00 · Special Offer AeroPaks offers a customized subscription plan that is costeffective and allows you to choose the number of downloads and Aerospace and Aerospace Material documents you needFind more information here

Cadmium Plating Mechanical Engineering General Discussion Eng Tips

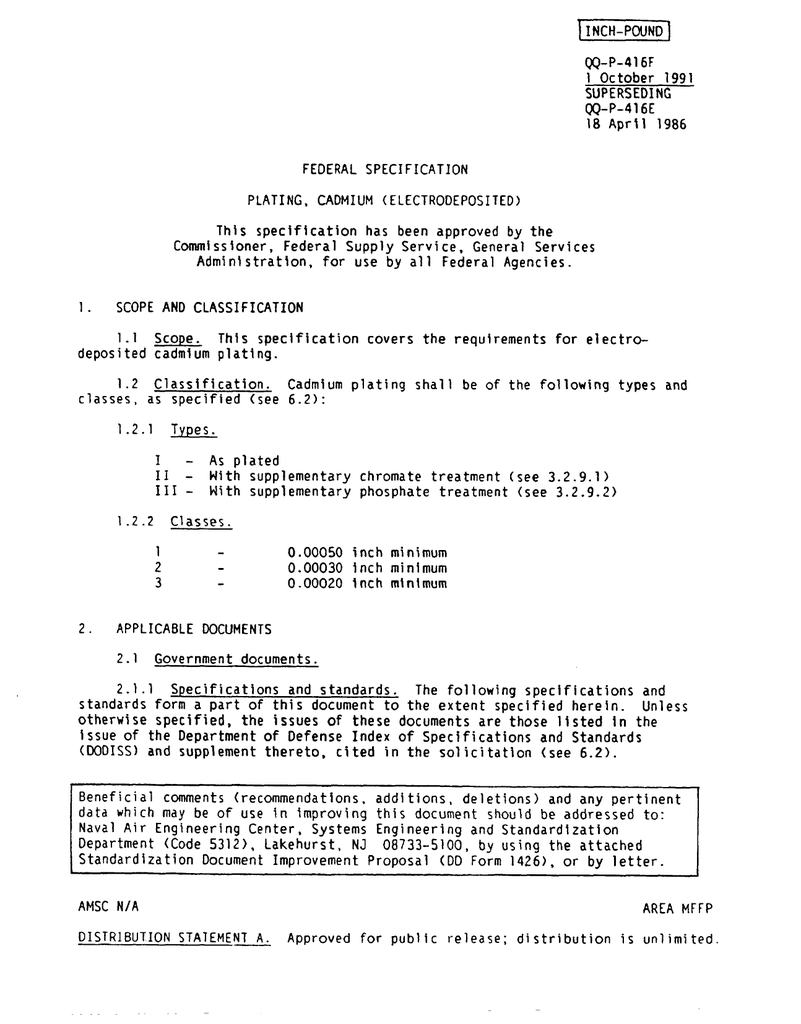

SAE AMSA8625 Type I Class 1 Anodize (Sulphuric) * SAE AMSA8625 Type II Class 1 Anodize (Hard) * SAE AMSA8625 Type III Class 1 Cadmium * SAE AMSQQP416 Type I Class 3 (Races) Cadmium (Supplementary Chromate Treatment) * SAE AMSQQP416 Type II Class 2 (Bodies) Cadmium (Vacuum Deposited) SAE AMSC87 ChromiumAnodized in accordance with MILA8625, Type II, Class 1 plus lubricant Cadmium Plate 0003" minimum thickness per SAE AMSQQP416 Class 2, Type IIQQP416F, FEDERAL SPECIFICATION PLATING, CADMIUM (ELECTRODEPOSITED) (01 OCT 1991) S/S BY SAEAMSQQP416, This specification covers the requirements for electrodeposited cadmium plating

NF Aluminum Cadmium, Olive Drab SAEAMSQQP416 Type II Class 2 over electroless nickel 1000 Conductive 65 to 175°C Glenair's standard olive drab cadmium finish P Stainless Steel Electrodeposited Nickel SAEAMSQQN290 Class 1 Grade F 500 Conductive 65 to 0°C Use ZM for electroless nickel alternativeCaD Plate Per aMs QQP416 tyPe ii Cl2 CaD Plate Per aMs QQP416 , tyPe ii Cl2 CPr CaD Plate Per aMs QQP416 tyPe ii Cl2 GreeN Par 90 CaD Plate Per aMs QQP416 , tyPe ii Cl2 Par 90 Or Bare TABLE 1 strength requirements – CCr274 (Class 1), CCr264 (Class 2), CCr244 (Class 3) Rivet Material Head ClassCadmium Plate C2 AMSQQP416 Type II Class 2 Chem Film MILDTL5541, Type I, Class 1A (Gold) Chrome AMS 2460 Gold MILDTL454, Type II, Class 0 Nickel Plate N AMSQQN290, Class 1, Grade G Passivate P AMS 2700 Method 1, Type2, Class 1 (copper sulfate test) Phosphate PH MILDTL, Type Z, Class 2 Silver Plate S ASTM 00 Tin Plate

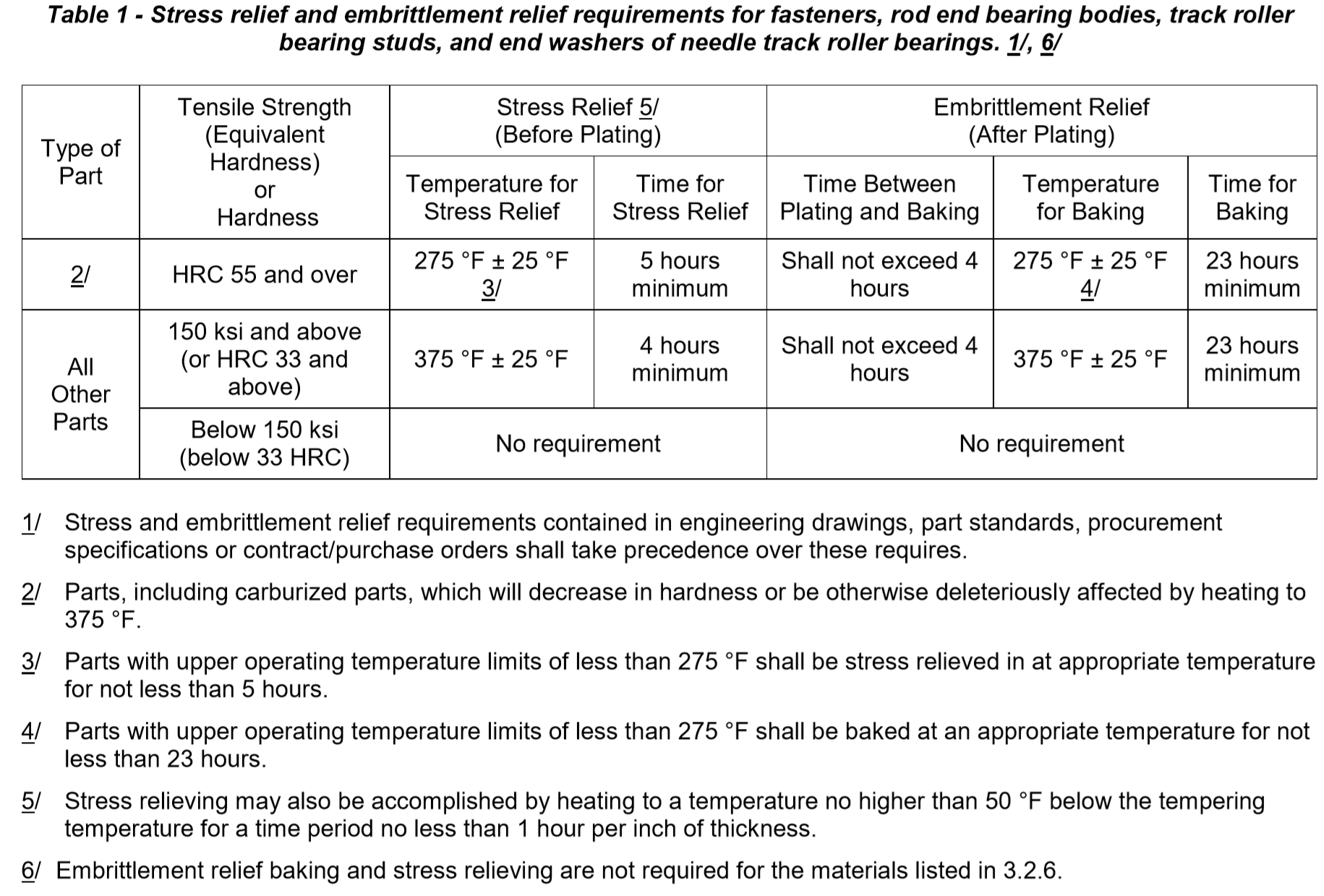

SPECIFICATION QQ – P – 416 / AMS – QQ –P – 416 Class 1 THICKNESS" min Class 2 THICKNESS" min Class 3 THICKNESS000" min Type I DETAIL As plated, no chromate Type II DETAIL With supplementary chromate treatmentUNJF3B Nut Hex, High Tensile, Steel Steel Type C1137 OF FEDSTD66 or Carbon or Alloy Steel MILS1222 (C1137 Steel May Contain from 015 TO 035 perCENT LEAD), Cadmium Plate, SAEAMSQQ P416 Type II, Class 2 N1610 SeriesRKEL W W VKEL To meet AS requirements Y ZincCobalt, Dark Olive drab ASTMB840

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Cadmium Type I, II Class 1, 2, 3 AMSQQP416 *QQP416 Electrodeposited Cleaning Surface Treatments MILS5002 TTC490 Chemical/Abrasive High Humidity Testing AMSSTD753 Method 101 Water Immersion AMSSTD753 Method 100 Copper Sulfate AMSSTD753 Method 102 Passivation AMS2700 *AMSQQP35 *QQP35 ASTM A 967 ASTM A 3806121 Type II temperature llmltatlons Chromate treatments (Type II) should not be used on plated parts that will not be coated and which will be continuously exposed to temperatures in excess of 150°F (66°C) or intermittently exposed for short periods to temperatures of approximately 300°F (149°C) or moreG Cadmium plate per AMSQQP416, Type II, Class 2, plus Kaylube molybdenum disulfide dry lubricant per AS5272, Type I GX3 Cadmium plate per AMSQQP416, Type II, Class 2 Channel Passivate per AMS2700 PERFORMANCE NASM FLOATABILITY From center of hole longitudinally 030 040, laterally 010 03 Method of

Cadmium Plating For The Aerospace Industry Har Conn

Ams Qq P 416 E Corrosion Heat Treating

FINISH Nut and retainer Cadmium plate per AMSQQP416, Type II, Class 2 and Kaylube molybdenum disulfide dry film lubricant coat per AS5212 ,Type I PERFORMANCE NASM APPLICATIONS For use with materials such as aluminium alloys, brass, copper and mild steels INSTALLATION DATA Use Kaylock tool number KT72 or KT74Finish Cadmium plated per AMSQQP416, Type II, Class 1 and baked Heat treated components per AMSH6875 Weight 06 lb 10 Threaded Stud 11 Threaded Stud Thread Size 3/4 UNF 3A Finish Cadmium plated per AMSQQPSAE AMSQQP416, Revision F, March 21 (R) Plating, Cadmium (Electrodeposited) General Usage Processes used for cleaning and cadmium deposition on components heattreated to, or having ultimate tensile strength of 152 ksi (1048 MPa) or higher tensile strength or 34 HRC or higher, should incorporate practices and procedures to minimize hydrogen embrittlement

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

American Ring True Manufacturing Solutions

T Cadmium, Bright AMSQQP416, TypeI, Class2 5 Cadmium, Olive drab AMSQQP416, Type II, Class 3 V VKEL AMSQQP416, TypeII, Class3 (Cadmium);Cadmium Plate, AMSQQP416, Class 2, Type I Cadmium Plate w/Chromate Dip, AMSQQP416, Class 2, Type II Cadmium plating is used on carbon steel to increase the corrosion resistance of the product The process of cadmium plating spiral retaining rings is costly and subjects the ring to the possibility of hydrogen embrittlementThis is a list of the plating, finishing, and other services we regularly provide We also do specialty and custom jobs If you do not find your process on our list, please contact our Sales Department (814) or request a quote with specific information about your project We'd like the opportunity to put our 90plus years of expertise in anodizing, plating, and polishing to work for

Sae Ams Qq P 416d 15 Sae Ams Qq P 416d 15 Plating Cadmium Electrodeposited

Cadmium Plating Mechanical Engineering General Discussion Eng Tips

AMSQQP416 Class I " minimum thickness Class II " minimum thickness Class III " minimum thickness Type I As plated Type II With chromate treatment Type III With phosphate treatment Colorless Irridescent Bronze Brown Olive Drab Yellow Forrest Green Primarily used to protect steel and cast iron against corrosion Chrome PlatingNickel Plating We process sulfamate nickel plating class 1 and class 2 with dull or satin finishes that are applied for corrosion protection The nickel plating process can be applied as anF5000 (*) Cadmium plate per AMSQQP416, Type II, Class 2 plus Kaylube molybdenum disulfide dry film lubricant per AS5272, Type I F5000X (*) Cadmium plate per AMSQQP416, Type II, Class 2 F5000 (*)CW Cadmium plate per AMSQQP416, Type II, Class 2 and carbowax PERFORMANCE NASM

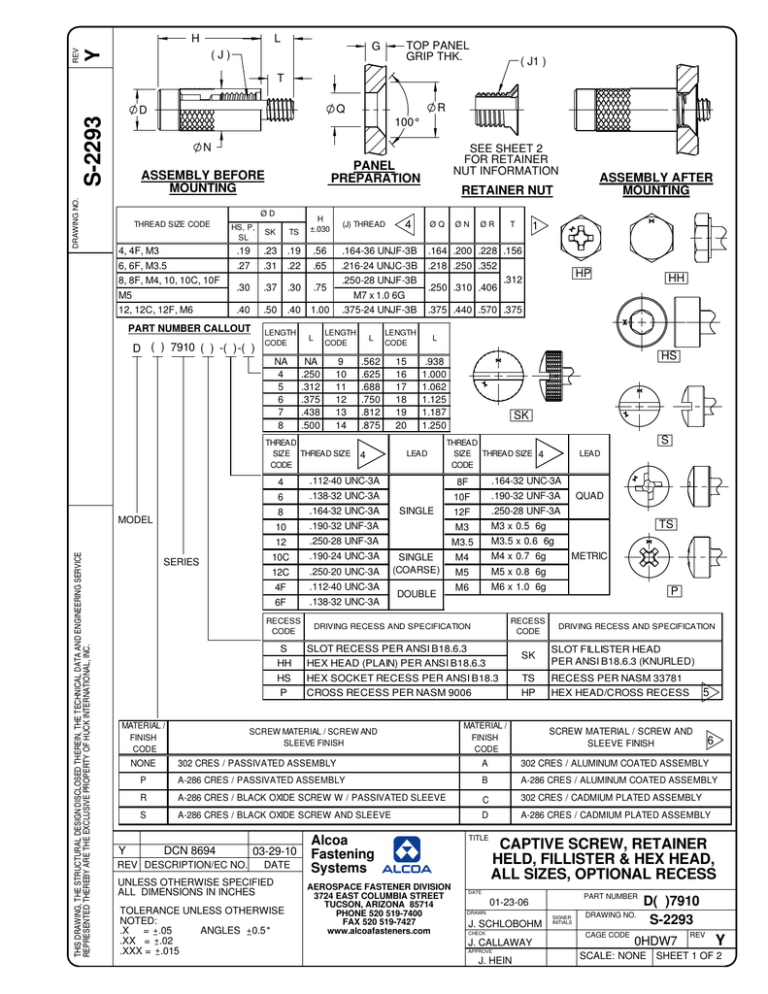

D7118

Countersunk Head Threaded Insert Closed End Keyless Unified On Pennengineering

Cadmium Plate per AMSQQP416, Type II, Class 2 150 KSI Minimum Tensile (Except Skirt) in 0348 lb View CAD 40G Alloy Steel per ASTM A304 Carbon Steel per ASTM A108 Cadmium Plate per AMSQQP416, Type II, Class 2 150 KSI Minimum Tensile (Except Skirt) in 0363 lb View CAD 40G Alloy Steel perAccordance with SAEAMSQQP416, Type II, Class 3 Plating code 2 electroless nickel in accordance with ASTM 33 Plating code 4 black anodize in accordance with MILA8625 Type II Class 2 Plating code 5 gold plated in accordance with ASTM B4 over electroless nickel in accordance with ASTM 3390II) on electrodepositedcadmium QQP416F The prime purpose of chromate finishes (Type platings is to retard or prevent the formation of white corrosion products on surfaces exposed to stagnant water, high humidity atmospheres, salt water, marine atmospheres, or

Item Kfn305c4 Kfn305 6 Point Deep C Bore On Howmet Aerospace

Surface Finishes For Steel Fasteners Wilson Garner Company

Adapter Plating Material Cadmium (SAE AMSQQP416, Type II, Class 3) Adapter Underplating Material Suitable Material per SAEAS (500 Hour Salt Spray) Industry StandardsCadmium plate per AMSQQP416, Type II, Class 2 /8/ CRES Silver plate for 800 degree Fahrenheit use per NASM to a 0002 minimum thickness on surfaces which can be touched by a (3/4 inch) diameter ball Threads shall show complete coverage, but thickness requirement on threads is waived Aluminum AlloyH Anodize, Black AMSA8625, Type II, Class 2 B Cadmium Plate, Black AMSQQP416, Type II, Class 3 X Cadmium Plate, Bright Over Electroless Nickel AMSQQP416, Type I, Class 3 ASTMB , SC2, Type I, Class 5 over AMSC, Class 4, Grade B E Cadmium Plate, Gold Irridite, Over Electroless Nickel

Ams Qq P 416 E Klzz15gdjqlg

Ams Qq P 416 E Klzz15gdjqlg

Finish Cadmium Plated Bolts Cadmium Plate Per AmsQqP416, Type II, Class 2 Embrittlement Requirement Per Nas4002 Chromium Plated Bolts Chromium Plate Per AmsQqC3, Class 2 On Shank Only All Other Surfaces Cadmium Plated No Chromium Within 0 Of Line Of Tangency Of Head To Shank Fillet Chromium In Thread Runout PermittedI H95(*)CW Cadmium plate per AMSQQP416, Type II, Class 2 and cetyl alcohol lubricantH95(*)CD Cadmium plate per AMSQQP416, Type II, Class 2 and Kaylube molybdenum disulfide dry lubricant per AS5272, Type IPERFORMANCE NAS 3350, Class IIIANOTES "C" and "W" dimensions apply before forming selflocking feature LessAMSQQP416 TYPE IWithout supplementary chromate treatment TYPE IIWith supplementary chromate treatment AMS 2400 CLASS 1 0005 Min CLASS 2 0003 Min CLASS 3 0002 Min TYPE I Clear TYPE IIGold, Olive Drab, Black Treatment Most commonly used plating High density of plate affords excellent corrosion resistance

Qq P 416 Type Ii Class 2 Pdf Aeqb Kiopkaen Site

Ccr274ss A Cres Solid Film Lube Passivate Ccr274cs P E R Per Per Per Ms604r Ams 5731 Astm A 493 Mil L Qq P 35 L F Pdf Free Download

SAEAMSQQP416 Type II Class 2 over electroless nickel 1000 Hour Salt Spray, Conductive 65 to 175°C No X Aluminum Unplated Yes Y Aluminum ZincCobalt, Olive Drab ASTM B 840 Grade 6 Type D over electroless nickel, 350 Hour Salt Spray, Conductive 65 to 175°C Yes ZN Aluminum ZincNickel, Olive Drab ASTM B841 Grade 5 over electroless nickelCadmium plate per AMSQQP416, type II, class 2 CRES NUT, SHELL AND WASHER Clean and passivate per MILDTL5002 NUT (WHEN CODED "C") Silver plate per AMS2410 ALUMINUM ALLOY WASHER Anodize or chemical film per NASM, except anodize shall be limited to type I or type II TITANIUM AND 174 PH RETAINER Passivate per AMS2700G AMSQQP416 Cadmium Plating Types g Type I – as plated g Type II – with supplementary Chromate Treatment g Type III – with supplementary Phosphate Treatment Thickness per Class Class 1 – " min thickness Class 2 – " min thickness Class

Approvals California Technical Plating Corp

Item 40s79 6a 40s79 Steel Stud Assemblies W Slotted Head On Howmet Aerospace

Amsqqp416 type i clear type ii gold class 1 " min thick class 2 " min thick rps1 astm b766 milstd870 ams 2400 zinc plate astm b633 type ii type iii class fe/zn25 sc4 25 min thick class fe/zn12 sc3 12 min thick class fe/zn8 sc2 8 min thick class1075 Spring Steel or Equivalent CAD Plate per AMSQQP416, Type II, Class 2 (Yellow) 1075 Spring Steel or Equivalent CAD Plate per AMSQQP416, Type II, Class 2 (Yellow) *Add thickness to MHF or MHL chart dimension H2 –Subtract Thickness from MHF or MHL chart dimension P2 04,M3 06, 35 08,M4 10, M5 12, M6 0221 0265 0265 0312Multichrome/ Microplate processes Type I and Type II cadmium plating conforms to industry standards AMSQQP416;

Cadmium Plating Sheffield Platers

Ams Qq P 416

UNF2B Nut Hex, Light, Steel, Post PlateCadmium Plate, SAEAMSQQ P416 Type II, Class 2 NM Series Product certifications may be available for this product Please email customerservice@biscoindcom to inquire about available certifications2 Dimensions are in inches and apply after finish and before application of lubricants HST75DU( )A = Solid film lube per AS5272, Type I Collar HST75( )A = Cadmium plate per AMSQQP416, Type I, Class 2 and cetyl alcohol lube Washer HST75( )DW = Solid film lube per AS5272, Type IThe cadmium plating shall be Type II on parts that will not subsequently be completely coated and Type III on parts that will subsequently be completely coated (see 522 and 523) 3281 Chromate Treatment The chromate treatment required for conversion to Type II shall be a treatment in or with an aqueous solution of salts, acids,

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Coating

UNJC3B Nut Reduced Hex, Steel, Cadmium Plate, SAE AMSQQP416, Type II, Class 2 NM107 Series Show more Product certifications may be available for this productH Anodize, Black AMSA8625, Type II, Class 2 B Cadmium Plate, Black AMSQQP416, Type II, Class 3 X Cadmium Plate, Bright over Electroless Nickel AMSQQP416, Type I, Class 3 ASTMB , SC2, Type I, Class 5 over AMSC, Class 4, grade B e Cadmium Plate, gold Irridite, over Electroless NickelCadmium plating provides a smooth, adherent surface that is free from blisters, pits, nodules, burning, or other defects when examined visually without magnification It also provides great corrosion resistance Contact ENS Technology for more information regarding FED QQP35C cadmium plating today

Flathead Threaded Insert Closed End Keyless Metric On Pennengineering

Sae Ams Qq P 416 R Plating Cadmium Electrodeposited

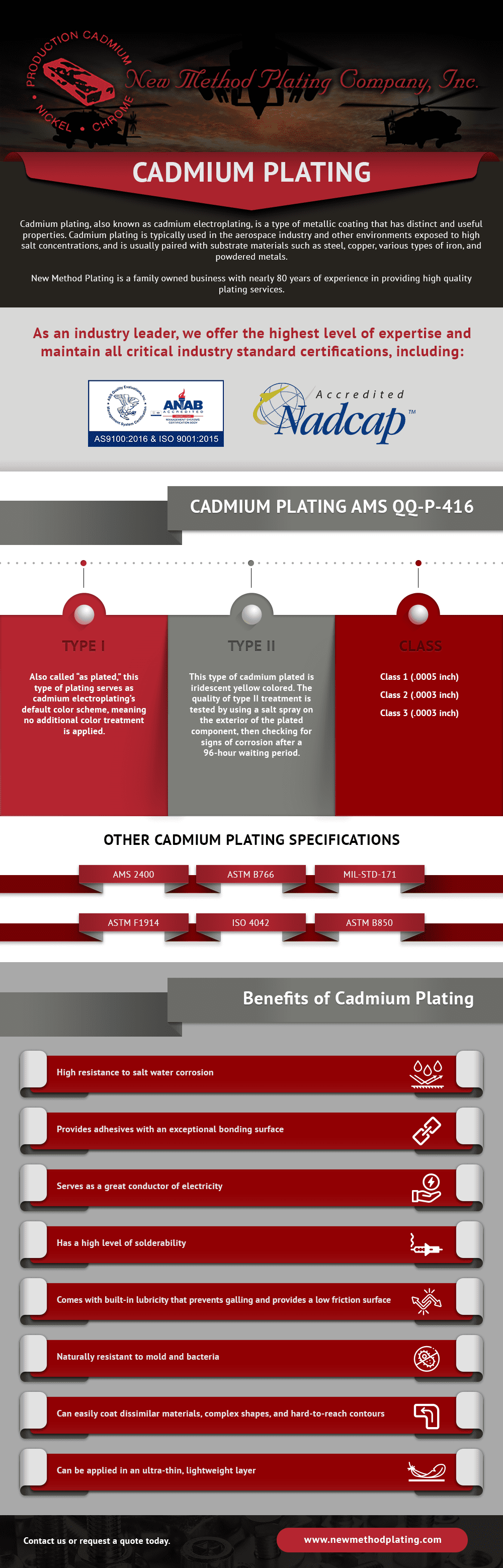

THICKNESS PER CLASS I – ″ minimum II – ″ minimum III – ″ minimum PLATING TYPES Type I – as plated Type II – w/ supplementary Chromate treatment INDUSTRY USES Aerospace, Automotive, Electronics, Defense, Marine and more

Qq P 416 Tech Information

Surface Finishes For Steel Fasteners Wilson Garner Company

Cadmium Plating Sheffield Platers

Passivation Of Stainless Steel Astm 67 Qq P 35 Ams 2700 Apt

Ams Qq P 416 E Corrosion Heat Treating

Thin Dense Chrome Plating Cadmium Plating Ams Qq C 3 Ams Qq P 416

Item G 5 4 13 G Gang Channel Narrow Deep C Bore On Howmet Aerospace

D 7910 Manualzz

Dummy Receptacle Mil Dtl 264

Ca Series Livelock Stud Nuts 100 C Sink Head Hex Cross Per Nas Specification Recess On Howmet Aerospace

Page 367 Is Rayfast Catalogue Issue 9 17

Cadmium Plating Sheffield Platers

Page 16 Circular Connector Backshells And Accessories

Cadmium Plating Cad Plating Ams Qq P 416 Techmetals Inc

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Cadmium Qqp 416 H E Plating Ltd Electroplaters In Toronto Ontario

Nasm Nut Datasheet Pdf Nut Equivalent Catalog

Cadmium Plating Macon Georgia

Ms 4 Datasheet Pdf Datasheet4u Com

Aerospace Ams Qq P 416 Rev E Material Aerospace Ams Qq P 416 Rev E Material Pdf Pdf4pro

Surface Finishes For Steel Fasteners Wilson Garner Company

Evaluation Of Alternatives To Electrodeposited Cadmium For Alcoa

Cadmium Plating New Method Plating Company Inc

Ams Qq P 416 E Corrosion Heat Treating

Qq P 416 Tech Information

Cadmium Plating Sheffield Platers